Substrate preparation:

The surface must be clean, dry, and load-bearing. Contaminants and adhesion-reducing substances such as formwork oils, remnants of building mortars and other materials, as well as peeling paint coatings, must be removed. Minor surface irregularities should be levelled with "ArmaTexture 1000" mortar, ensuring the leveling layer does not exceed 10 mm.

Highly absorbent surfaces and those contaminated with dust should be thoroughly cleaned and treated with the fixing primer "UniGrund" or concentrated primer "GrundKonzentrat".

Glossy surfaces must be roughened and primed with "PutzGrund 117".

Mixing instructions:

Carefully pour the contents of the "VabiO" package (15 kg) into a container with 4.5–5.5 liters of clean water at room temperature and mix with a low-speed electric mixer until a homogeneous consistency is achieved. Let the mix sit for approximately 10 minutes, then remix. If needed, slightly adjust the consistency with a small amount of water. Depending on ambient conditions, the working time of the mix is around 2 hours after preparation.

Once the mix starts to harden and lose workability, it must not be re-diluted with water for further use.

Application:

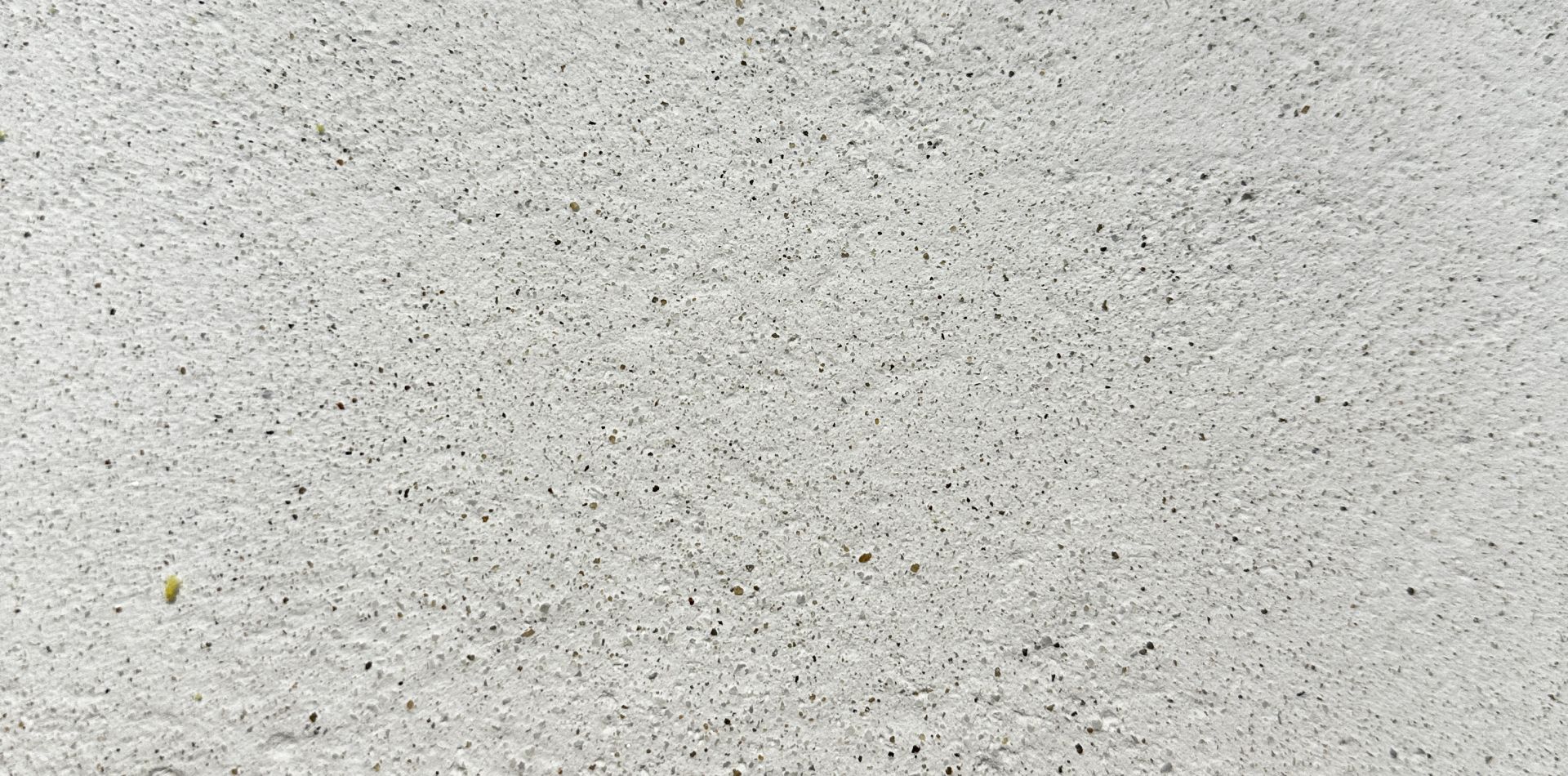

"VabiO" mortar is recommended for creating aesthetically rich and architecturally expressive surfaces that imitate natural materials. It can be used with various decorative additives, such as fired clay "Cocciopesto", crushed Black Sea shells "ShellGrit", etc. Application requires a high level of craftsmanship and experience.

The ready mix should be evenly applied to the surface with the required layer thickness. After 2–4 hours (under standard conditions), when the material has gained initial strength but remains moist enough for processing, gently wash the surface with a clean, damp sponge to reveal the color inclusions of sand and added particles.

This process should be carried out carefully to preserve the integrity of the texture. A second washing is recommended after 12 hours to fully uncover the aggregates. Allow the surface to dry completely and gain full strength.

Once the plaster has fully cured, the surface can be treated with special wax emulsions such as "Velatura Vintage matt", "Decor Wax", "Special Wax", protective soap "Savon", or other suitable finishes. This significantly enhances the aesthetic of the external insulation system while improving durability, water resistance, and dirt repellency.

To create the appearance of natural stone or brick cladding, it is recommended to imitate joints during the setting process using a level, marking tool, and straight edge.