The surface must be clean, dry, level, capable of bearing a load, and meet the preparation conditions according to the requirements. Contaminants and substances that negatively affect adhesion must be removed, and any irregularities or chips must be leveled with appropriate materials, such as "Klebe-und Armierungs Masse AM 195." Highly absorbent surfaces must be primed with materials such as "UniGrund" or "GrundKonzentrat." Glossy surfaces, such as concrete, must be primed with "Acryl PutzGrund 117." To create a uniform optical effect and improve adhesion on the prepared base, it is recommended to use "Acryl PutzGrund 117" primer, tinted to match the primary color of the "MosaikPutz" plaster. To ensure the quality of the work performed, it is recommended to take a 48-hour technological break after priming with "Acryl PutzGrund 117."

Base requirements:

Energy-saving system D "ThermoELF®." A curing period of 6 days from the start of XPS plate installation, application of the reinforcing layer, and priming before applying the mosaic plaster.

Mineral plaster. Curing for at least 28 days. Moisture content not more than 4%.

Monolithic concrete. Curing for at least 90 days. Moisture content not more than 4%.

Material preparation:

"MosaikPutz" is a ready-to-use dispersion plaster. Before use, the contents of the package must be thoroughly mixed with a low-speed mixer.

Work execution:

Apply evenly in a layer with the maximum grain thickness using a stainless steel trowel or wide spatula and spread evenly over the surface. Smoothing of the mosaic plaster should be done in one direction immediately after its application.

Attention! When applying mosaic plaster, the dispersion has a milky-white color, which turns into a transparent, durable film within 48 hours.

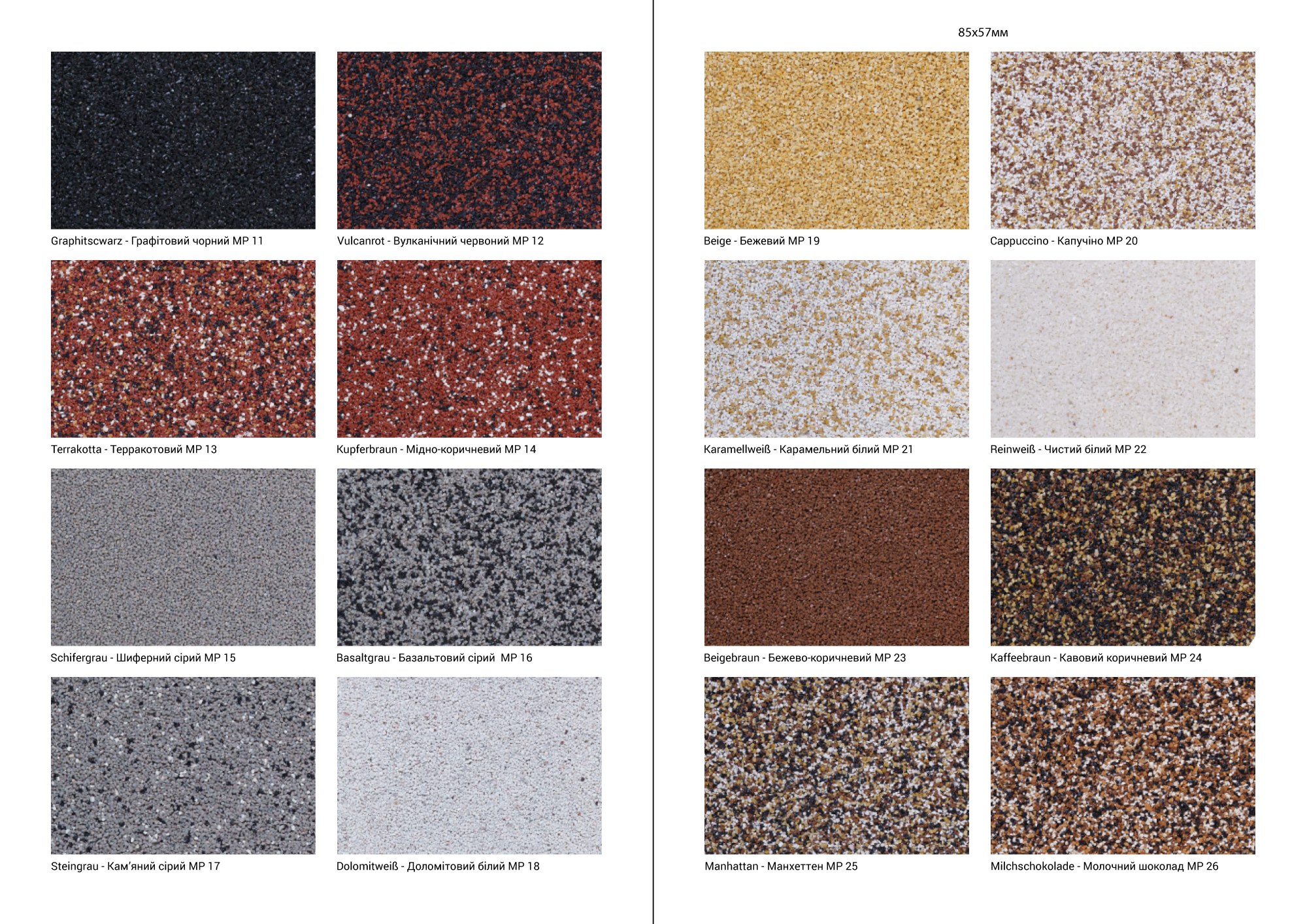

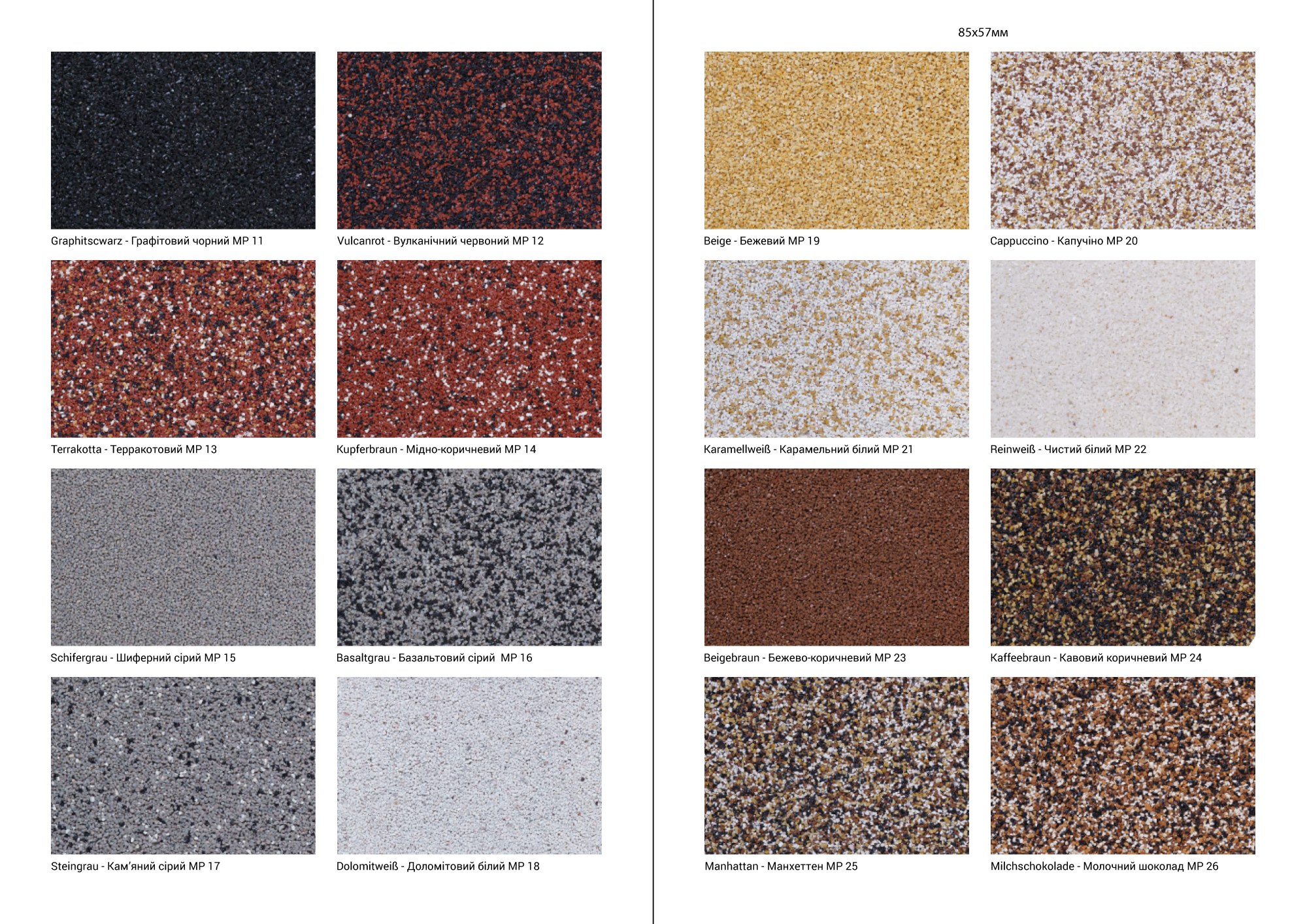

Color options: