Preparation of the mixture:

Mix all three components by the following ratio: 0.125 kg of component A + 0.125 kg of component B + 1 kg of component C.

Use a mechanical mixer with a spiral beater for mixing. To achieve the best result, first thoroughly mix components A and B until a homogeneous creamy emulsion is obtained. Then gradually add component C with constant stirring until a homogeneous mixture without lumps is obtained.

Components can be mixed manually as well. It is recommended to stir the mixture from time to time in order to keep in uniform. If it is necessary to reduce the viscosity in the finished mixture you can add about 3% water. In case of application to large areas, it is recommended to add 5-8% water to the finished mixture. The working life of the mixture is about 1 hour at a temperature of 25°C and a relative humidity of 60%.

Touch-dry time is about 6-8 hours, full-drying time for grinding is about 24 hours.

Surface preparation and application:

The base must be strong and dry, without dust and efflorescence. Restore the surface using appropriate materials if necessary. Treat the surface with suitable agents to remove mold and fouling if necessary. Remove any efflorescence and peeling coatings with appropriate tools. Prime weak and crumbling bases with Elf™ TiefGrund primer. Prime lime bases with Elf™ VINILGRUND D 14 primer. For hard bases you can alternatively use Elf Decor™ quartz primers - Quartz Primer or Quartz Primer Nero.

Use a spatula or a plastering trowel for Alchimia application. Drying time: about 24 hours depending on the base type, its absorption and environmental conditions.

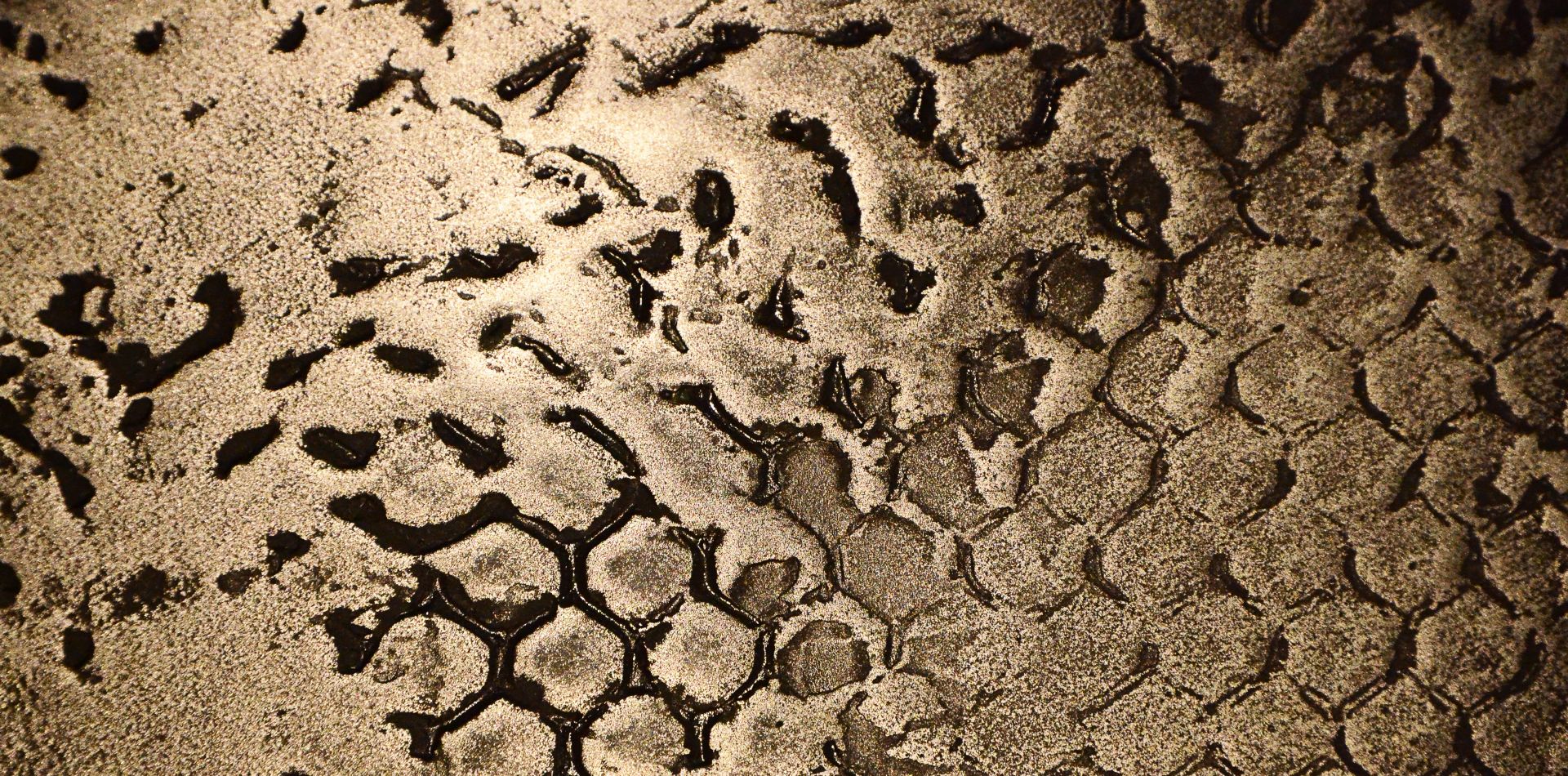

Grinding and polishing:

Grinding and polishing are necessary to obtain the final aesthetic typical appearance of natural polished metal. Use a grinder equipped with a speed controller and connected to a vacuum cleaner. At the first stage, in order to process a completely dried coating, use grinding discs of the following grain sizes in sequence: 150, 240, 320, 500, 800. Processing should be done at a low speed to avoid overheating of the surface and its damage. Continue polishing of the surface with abrasive discs, with the following grain sizes: 1000, 2000, 3000, until the desired smoothness is obtained. We recommend using special foamed polishing discs together with Alchimia Mirror Glaze polishing paste at this stage. That will ensure the quick removal of all grinding defects, while leaving a coating without curls.

Clean the surface with a microfiber cloth with a non-abrasive (neutral) detergent at the end of the polishing process. Then apply a thin layer of Alchimia Polish protective polish to the surface and polish the surface with a paper towel or cotton rags. Alchimia Polish protects the finished coating from stains or prints and provides long-lasting surface maintenance.